EMU-1 NMEA 2000® Engine Monitoring Unit

EMU-1-BAS

EMU-1 - Convert your Analog engine data to NMEA 2000.

(Please note that an Actisense NGX-1-USB or NGX-1-ISO, is required to configure the EMU-1. This is an optional item and is not included with the EMU-1)

The Actisense EMU-1 is a specialized analogue to NMEA 2000 Gateway which converts data from analogue engine senders into NMEA 2000. The EMU-1 enables NMEA 2000 display devices to monitor the engine on a vessel.

The EMU-1 has a PC based configuration tool that allows the settings inside the EMU-1 to be changed to best suit the engine it is working with, making it a flexible solution for many engine makes and models. Capable of measuring a wide range of engine parameters, the EMU-1 reports how the engine is operating and shares the information across the network.

Designed to simplify the conversion of analogue engine parameters (e.g. Temperature, pressure and RPM) into NMEA 2000 engine PGNs, the EMU-1 simplifies processes and reduces the number of input/output wires required at each engine. Additionally, the EMU-1 also supports the conversion of analogue transmission parameters and battery status to the associated NMEA 2000 PGN's.

The two-part screw terminal connection system allows for an easy pluggable connection to an engine wiring harness.

Multiple engines are supported by the setting of the engine instance using the EMU-1 configuration tool. Currently one EMU-1 per engine is supported. Support for multiple engines on a single EMU-1 is currently planned as a future firmware update.

The customized case ensures that the electronics are sealed while allowing quick access to the electrical connections.

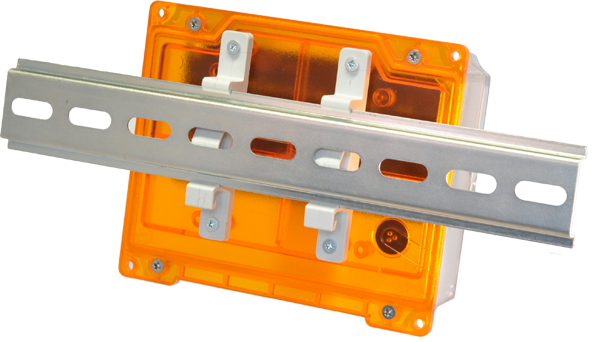

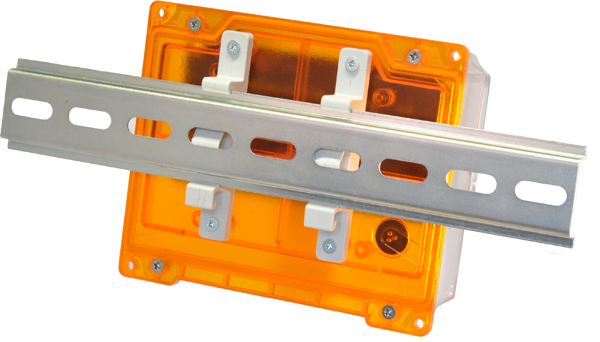

An optional DIN rail mounting kit is also available. The kit is suitable for use with a top hat rail, type EN 50 022 or a G section rail, type EN 50 035. Please order the DIN rail kit using part number: DIN-KIT-1.

It is recommended that an Actisense NGX-1 NMEA 2000 Gateway is available for every EMU-1 installation as the EMU-1 can not be configured without one. The NGX-1 can also be used to update the Firmware, connect the Configuration Tool and display data on a PC for diagnostic and information purposes, using NMEA Reader. Please visit the Actisense Engine Monitoring Solution page for product details.

Now Includes Support for Tilt & Trim Tabs!

FEATURES

- Enables analogue signals to be converted to NMEA 2000 messages

- Convert signals from up to two engines (that share a common ground) with a single EMU-1

- 6 gauge / parameter inputs

- 4 alarm inputs

- 2 additional auxiliary inputs

- 2 Tacho inputs

- Customised IP65 case

- Diagnostic LED’s

- Wide power compatibility of 9 to 35 Vdc

BENEFITS

- No need to change an existing engine

- Easy installation

- Easy to configure to suit the connected engine

- Connect signals from fluid level gauges (that share a common ground with the engine) to NMEA 2000®

- Optional DIN rail mounting kit available

- Total engine hours are logged by the monitoring of engine Tach (RPM) input

Ordering Information

(Part number/s)

- EMU-1

CONFIGURATION INFORMATION

Every EMU-1 MUST be configured to work with each installation.

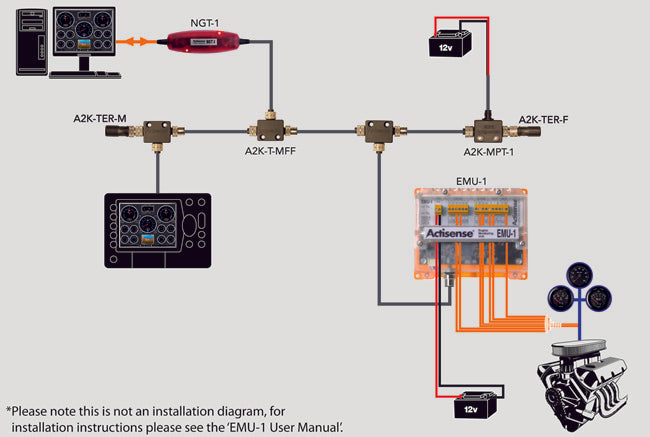

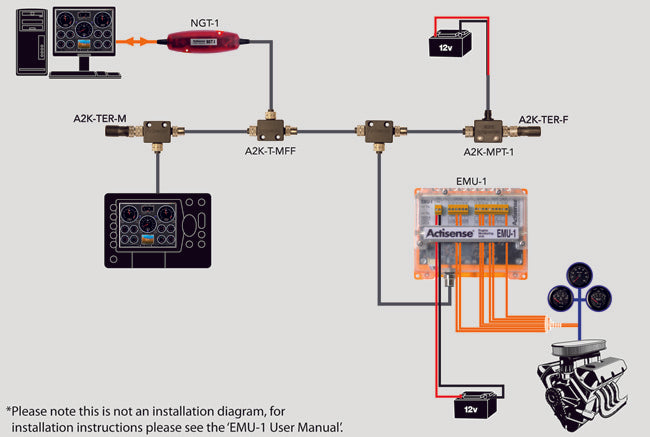

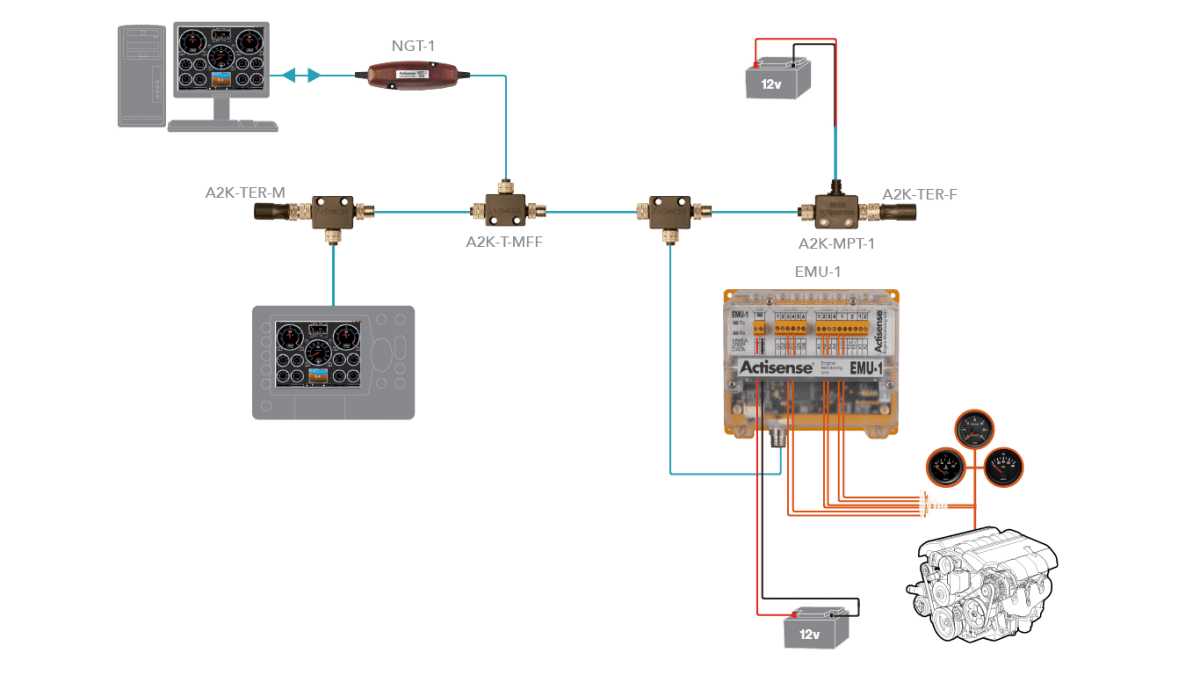

NETWORK DIAGRAM

TECHNICAL SPECIFICAIONS

| Power Supply | |

| Supply Voltage | 9 to 35V DC |

| Supply Current | Typically < 25mA @ 12V DC |

| Supply Protection | Continuous reverse polarity protection and load dump protection (meets SAE J1113) |

| Supply Connector | Pluggable 2-way screw terminal, 3.5mm pitch |

| Supply Voltage (NMEA 2000 Port) | 9 to 29V DC |

| Supply Current (NMEA 2000 Port) | < 20mA @ 12V DC from NMEA 2000 bus |

| Load Equivalent Number (LEN) | 1 |

| Supply Protection (NMEA 2000 Port) | Continuous reverse polarity protection and overvoltage protection to 40V |

| NMEA 2000 Port – In/Out | |

| Compatibility | Fully NMEA 2000 certified |

| Galvanic Isolation | 2500V input to ground, 1500V output to ground using ISO-Drive |

| Speed / Baud Rate | 250kbps |

| NMEA 2000 Connector | M12 male (A coded) connector |

| Gauge Inputs | |

| Voltage Range | 0 to 35V DC |

| Input Impedance | > 50kΩ |

| Sender Feed | 0, 4 or 18mA |

| Accuracy | <= 2% |

| Input Connector | Pluggable 6-way screw terminal, 3.5mm pitch |

| Input Protection | Overvoltage protection to ±40V |

| Alarm Inputs | |

| Voltage Range | 0 to 37V DC |

| Input Impedance | > 50kΩ |

| Threshold Voltage | Configurable, default is 5V |

| Alarm Polarity | Configurable, default is alarm on low input |

| Accuracy | <= 2% |

| Input Connector | Pluggable 4-way screw terminal, 3.5mm pitch |

| Input Protection | Overvoltage protection to ±40V |

| Tacho Inputs | |

| Voltage Range | ±3 to ±60V |

| Input Impedance | > 100kΩ to ground |

| Input Pulse Range | 4 to 50,000Hz |

| Accuracy | <= 1% |

| Sender Compatibility | Ignition coil, alternator (“W”, “R” or “AC”) terminal, hall effect, VR or inductive sender |

| Threshold | Automatically adjusts to signal level |

| Input Connector | Pluggable 4-way screw terminal, 3.5mm pitch |

| Input Protection | Can withstand an ignition pulse to ±500V |

| Engine Log | |

| Engine Hours | 2 separate engine hour logs internally connected to the tacho Inputs. Hours are logged when RPM is present, stored in non-volatile memory |

| Mechanical | |

| Housing Material | Polycarbonate |

| Protective Lid Material | Polycarbonate |

| Sealing Materials | Expanded silicone foam gasket, closed cell polyurethane splash guard and ePTFE waterproof vent |

| Dimensions | 127mm (L) x 112mm (W) x 48mm (H) |

| Weight | 250g |

| Mounting | 4 x 3.5mm lugs to allow panel mount with self tapping s/s screws (included), optional DIN Rail mount available on request |

| Approvals and Certifications | |

| Fully NMEA 2000 Certified | |

| EMC | EN 60945 (sections 9 & 10) |

| Environmental Protection | IP66 (PCB housing) |

| Operating Temperature | -20°C to +55°C |

| Storage Temperature | -30°C to +70°C |

| Recommended Humidity | 0 – 93% RH |

| Warranty | Manufacturer's 3 years |

Video